The automotive industry is constantly evolving and becoming more and more technologically advanced. With this advancement, it has become necessary for automotive engineers to utilize Computer Aided Engineering (CAE) in order to stay ahead of the game. In this blog, we will discuss the best practices and considerations for using CAE in automotive design.

What is Computer Aided Engineering?

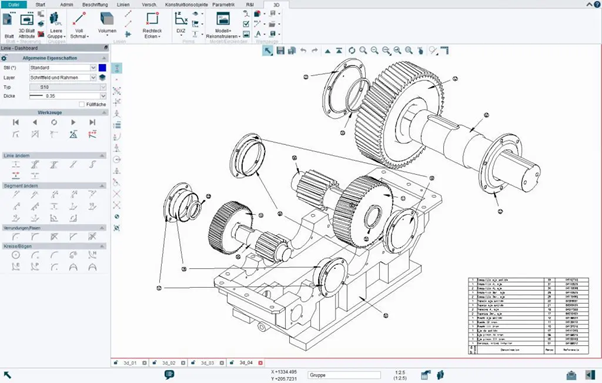

Computer Aided Engineering is the use of computer software to analyze and simulate the behavior of a design before it is physically manufactured. This allows engineers to evaluate different designs and make changes to optimize their performance before they are built. In the automotive industry, CAE is used to analyze a variety of things, including crash worthiness, fuel efficiency, and emission levels.

Best Practices for Using CAE in Automotive Design

-

Start Early

Starting the CAE process early in the design phase allows engineers to make changes before the design is finalized. This can result in more efficient and effective designs, as well as reducing the time and cost required for physical testing.

-

Use Appropriate Software

There are many different CAE software programs available, each with its own strengths and weaknesses. It is important to choose a software that is best suited for the specific needs of the design project. It is also important to keep in mind the experience and skill level of the engineers using the software.

-

Use Accurate Data

The accuracy of the CAE simulation is only as good as the data used to input into the software. It is important to ensure that all data is accurate and up-to-date in order to get the most accurate results.

-

Consider All Load Cases

In order to get a comprehensive understanding of the behavior of the design, it is important to consider all relevant load cases. This includes static loads, dynamic loads, and thermal loads.

-

Validate Results

It is important to validate the results of the CAE simulation in order to ensure that they are accurate. This can be done through physical testing or through comparison with existing designs.

Considerations for Using CAE in Automotive Design

-

Cost

CAE software can be expensive, and the cost of hardware and software upgrades can also be a consideration. It is important to weigh the cost of using CAE against the potential benefits.

-

Time

CAE simulations can take a significant amount of time to run, and the results may not be available immediately. It is important to plan for the necessary time and resources for the CAE process.

-

Expertise

Using CAE requires a certain level of expertise, and it is important to ensure that the engineers involved in the design process have the necessary skills and knowledge. This may require additional training and resources.

Conclusion

Computer Aided Engineering is a valuable tool in the automotive design process. By utilizing CAE, engineers can analyze and optimize designs before they are physically manufactured. The best practices for using CAE in automotive design include starting early, using appropriate software, using accurate data, considering all load cases, and validating results. The considerations for using CAE include cost, time, and expertise. By keeping these best practices and considerations in mind, automotive engineers can take full advantage of the benefits of CAE and produce more efficient and effective designs.